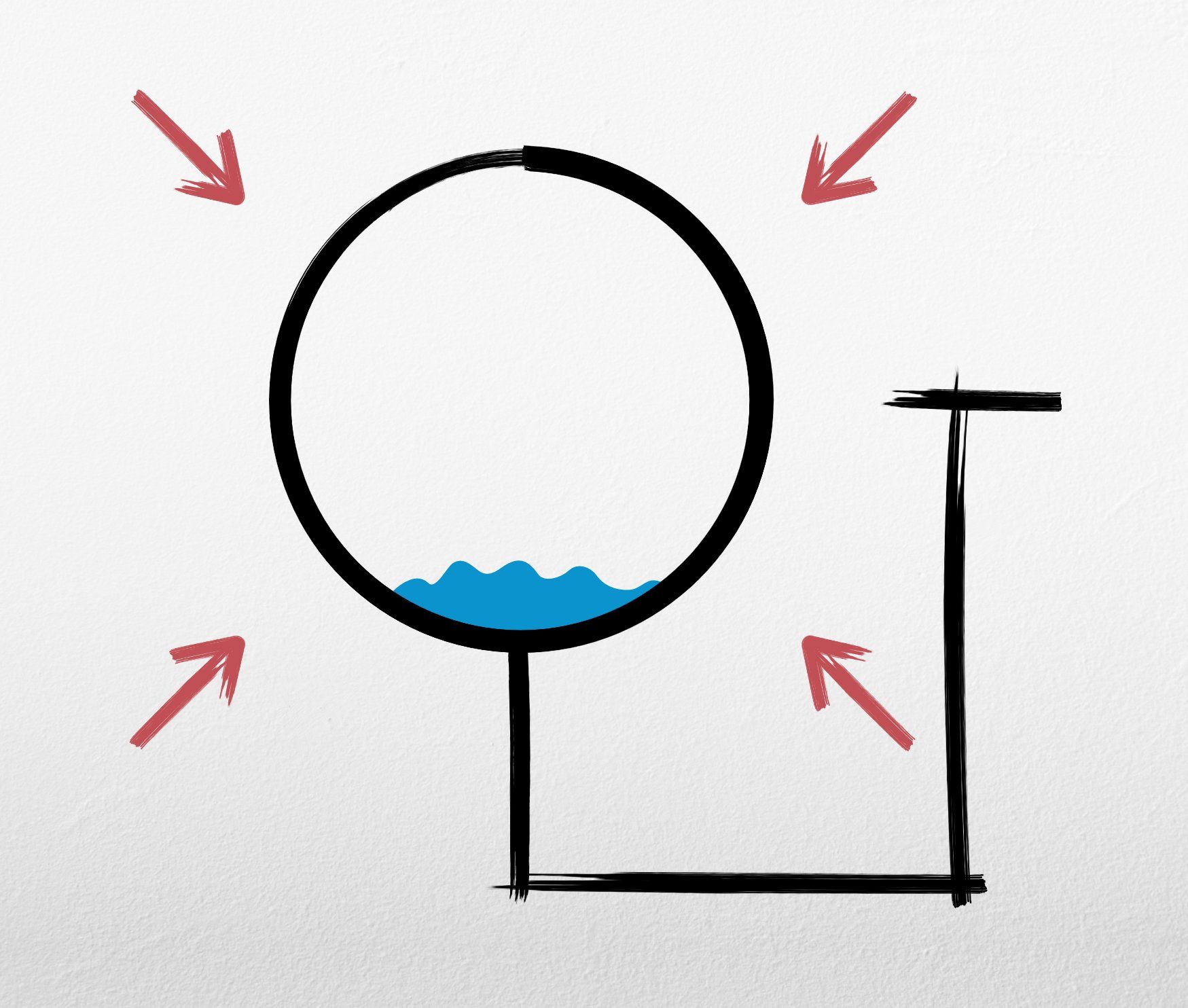

HOW IT WORKS

A reusable spring loaded device to hold hollow objects in place accurately during the Rotational Moulding production process and allows for movement of the object and device during or after the process.

Implemented on rotational moulding machines - replacing the currently used bolt feature.

The spring in the device will allow it to move with the plastic as it cools rather than being rigid and thus creating pressure at the seal.

BENEFITS

Designed to pop out of the plastic mould with simple compression while preserving the seal in comparison to the bolt twist method.

The device is suitable for any production process that requires a hollow object to be held in position through a hole in the surface, where there is restricted access to both sides at once.